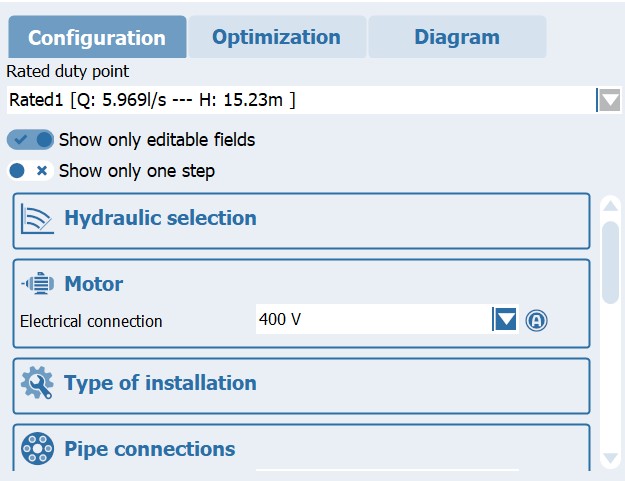

In the configuration area, the product is assembled by assigning the required components to the pump.

|

The area is divided into sections corresponding to the configuration steps.

The header contains a combo box where the design operating point can be defined. This box is active if more than one operating point has been specified. If only one operating point has been specified, this box is inactive.

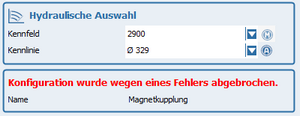

Configurable components are displayed in a combo box. In these boxes, lists of available components can be opened using the button. Additionally, an icon is displayed behind these boxes, indicating the status of the currently selected component.

◻Automatic: The component was selected automatically based on the operating data. ◻Manual: The component was explicitly selected or specified by the user. ◻Defaults: Entries are marked as preferred if a data set is characterized by multiple terms and a higher-level entry is manually selected. For example, selecting a specific motor version for the motor results in the motor being marked as a default. However, if a specific motor is selected, e.g., "XY 132L," it is uniquely described by the higher-level terms and results in the "Manual" marking. ◻In the direct pump selection and the hydraulic selection, the delivery time is visible under the current configurations. The calculated delivery time is updated as soon as elements in the configuration are changed.

|